Epoxy coating is a popular choice for aircraft hangar flooring due to its durability, chemical resistance, and ease of maintenance. In this article, we will discuss the benefits of epoxy coating for aircraft hangars and provide tips for selecting the best option.

What is Epoxy Coating?

Epoxy coating is a two-part system that consists of a resin and a hardener. When the two components are mixed together, a chemical reaction occurs that forms a strong, durable coating. Epoxy coating is commonly used in industrial and commercial settings due to its resistance to chemicals, abrasion, and impact. It is available in a variety of colors and textures, making it a versatile option for aircraft hangar flooring.

Benefits of Epoxy Coating for Aircraft Hangars

- Durability

Aircraft hangars require a flooring option that is durable and able to withstand the weight and impact of heavy aircraft and equipment. Epoxy coating is a strong, resilient option that can withstand heavy traffic and impact. It is also resistant to wear and tear, ensuring that the flooring will last for years to come.

- Chemical Resistance

Aircraft hangars often have chemicals such as oils, fuels, and hydraulic fluids present. These chemicals can damage traditional flooring options, leading to costly repairs and replacements. Epoxy coating is highly resistant to chemicals, making it an ideal choice for aircraft hangar flooring. It can withstand exposure to harsh chemicals without deteriorating or becoming damaged.

- Easy Maintenance

Aircraft hangars require a flooring option that is easy to maintain, as downtime for maintenance can result in lost productivity and revenue. Epoxy coating is easy to clean and maintain, requiring only regular sweeping and occasional mopping to keep it looking its best. It is also resistant to stains, ensuring that spills and other messes can be easily cleaned up.

- Slip-Resistance

Aircraft hangars can be hazardous environments, with personnel and equipment constantly moving around. Slippery flooring can lead to accidents and injuries. Epoxy coating can be customized to include anti-slip additives, making it a safe choice for aircraft hangars. This helps to reduce the risk of slips and falls, creating a safer work environment.

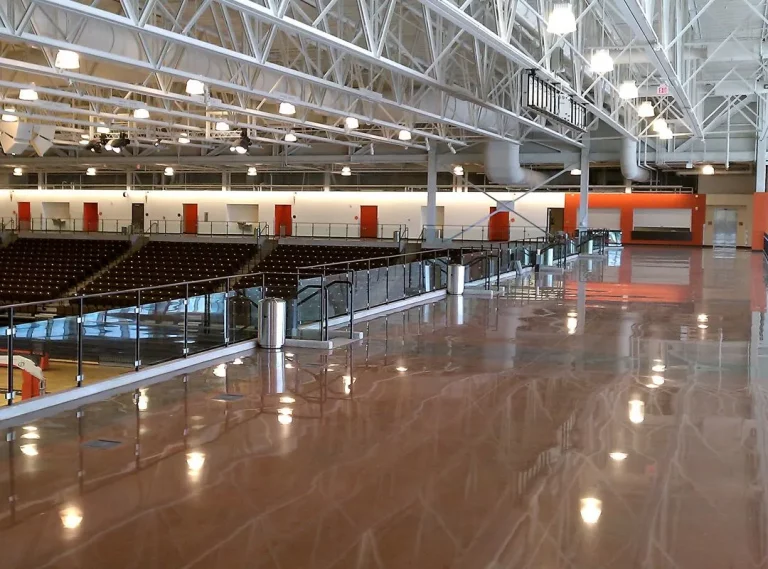

- Aesthetically Pleasing

Epoxy coating is available in a variety of colors and textures, making it a versatile option for aircraft hangar flooring. This allows you to customize the flooring to match the aesthetic of your hangar. It can also enhance the overall appearance of the hangar, creating a more professional and polished look.

Tips for Selecting the Best Epoxy Coating for Aircraft Hangars

- Evaluate the Needs of Your Hangar

Before selecting an epoxy coating for your aircraft hangar, it is important to evaluate the specific needs of your hangar. Consider factors such as the weight and size of the aircraft and equipment, as well as the presence of chemicals and other hazards. This will help you to select an epoxy coating that is able to withstand the demands of your hangar.

- Consider the Type of Epoxy Coating

There are several types of epoxy coatings available, each with different properties and characteristics. For example, some epoxy coatings are designed for high traffic areas, while others are more suited for areas with exposure to harsh chemicals. Consider the type of epoxy coating that will best meet the needs of your hangar.

When it comes to choosing the best epoxy coating for aircraft hangars in the aerospace industry, there are several factors to consider. The flooring needs to be durable, chemical resistant, easy to clean, and able to withstand heavy foot and vehicle traffic. In this article, we will explore the best epoxy coating options for aircraft hangars in the aerospace industry.

- Epoxy Novolac Coatings

Epoxy Novolac coatings are one of the best options for aircraft hangars in the aerospace industry. These coatings are designed to withstand harsh chemicals, high temperatures, and heavy traffic. They are formulated with a higher level of cross-linking, making them more resistant to chemicals and abrasion than traditional epoxy coatings. Epoxy Novolac coatings are also resistant to ultraviolet (UV) radiation, which can cause yellowing and fading in traditional epoxy coatings.

- Polyurethane Coatings

Polyurethane coatings are another excellent option for aircraft hangars in the aerospace industry. These coatings provide excellent abrasion and chemical resistance, making them ideal for high-traffic areas. They also have a high level of UV resistance, which makes them ideal for areas with high sun exposure. Polyurethane coatings are available in a range of colors and can be customized to meet specific design requirements.

- Epoxy Mastic Coatings

Epoxy mastic coatings are a thick, high-build coating that provides excellent adhesion and abrasion resistance. These coatings are ideal for repairing and protecting concrete surfaces in aircraft hangars. Epoxy mastic coatings are available in a range of colors and can be customized to meet specific design requirements.

- Epoxy Quartz Coatings

Epoxy quartz coatings are a decorative and durable option for aircraft hangars in the aerospace industry. These coatings consist of a clear epoxy resin mixed with colored quartz granules. The result is a slip-resistant, durable surface that is resistant to chemicals and abrasion. Epoxy quartz coatings are available in a range of colors and can be customized to meet specific design requirements.

- Conductive Epoxy Coatings

Conductive epoxy coatings are a specialized type of epoxy coating designed for use in areas where static electricity needs to be controlled. These coatings are ideal for aircraft hangars where the risk of electrostatic discharge (ESD) is high. Conductive epoxy coatings help to prevent damage to sensitive equipment and components by dissipating static electricity.

Choosing the best epoxy coating for aircraft hangars in the aerospace industry requires careful consideration of several factors, including durability, chemical resistance, ease of cleaning, and slip resistance. Epoxy Novolac coatings, polyurethane coatings, epoxy mastic coatings, epoxy quartz coatings, and conductive epoxy coatings are all excellent options for aircraft hangars. To ensure the best results, it is important to work with a reputable epoxy flooring contractor with experience in the aerospace industry. They can help you choose the right epoxy coating for your aircraft hangar and ensure professional installation for maximum durability and performance.

- Select the Right Color and Texture

Epoxy coating is available in a variety of colors and textures. Consider the color and texture that will best match the aesthetic of your hangar, while also providing slip resistance and safety.

- Hire a Professional Installer

Epoxy coating requires specialized equipment and knowledge to install properly. Hiring a professional installer can ensure that the epoxy coating is applied correctly and

correctly, resulting in a seamless, long-lasting finish.

- Competitive Pricing

Priority One Epoxy Flooring offers competitive pricing for their epoxy coating services. They understand that budget is an important consideration for many clients, and they work with each client to provide a flooring solution that fits within their budget.

- Excellent Customer Service

Priority One Epoxy Flooring is committed to providing excellent customer service. They work closely with each client to understand their unique needs and provide personalized solutions. They also offer ongoing support and maintenance to ensure that your flooring continues to look and perform its best.

Epoxy Coating Process

The process of applying epoxy coating to aircraft hangar flooring typically involves the following steps:

- Surface Preparation

Before applying epoxy coating, the surface of the flooring must be thoroughly cleaned and prepared. This may involve grinding, shot blasting, or other methods to ensure that the surface is clean, level, and free from contaminants.

- Primer Application

Once the surface is prepared, a primer is applied to the flooring. This helps to improve the adhesion of the epoxy coating to the substrate.

- Epoxy Coating Application

The epoxy coating is then applied to the flooring using specialized equipment. The coating is typically applied in multiple layers to ensure a strong, durable finish.

- Curing

After the epoxy coating is applied, it must be allowed to cure. This typically takes between 24 and 72 hours, depending on the type of epoxy and the environmental conditions.

- Finishing

Once the epoxy coating has cured, a finishing coat may be applied to the surface. This helps to enhance the appearance of the flooring and provide additional protection.

Maintenance of Epoxy Coated Aircraft Hangar Flooring

To ensure that your epoxy coated aircraft hangar flooring continues to look and perform its best, it’s important to follow a regular maintenance routine. This may include the following:

- Sweeping or Vacuuming

Regular sweeping or vacuuming of the flooring can help to remove debris and prevent scratches or damage.

- Mopping

Occasional mopping with a mild detergent can help to remove dirt and grime from the surface of the flooring.

- Avoid Harsh Chemicals

While epoxy coating is highly resistant to chemicals, it’s important to avoid using harsh chemicals on the flooring. This can help to prevent damage or discoloration.

- Address Spills Immediately

If a spill occurs on the flooring, it’s important to address it immediately. Use a clean cloth or mop to absorb the spill and avoid letting it sit on the surface.

Conclusion

Epoxy coating is an excellent flooring option for aircraft hangars. It provides durability, chemical resistance, easy maintenance, slip-resistance, and a customizable aesthetic. Priority One Epoxy Flooring is a leading provider of high-quality epoxy coating services for aircraft hangars and other commercial and industrial spaces. With over 10 years of experience, quality materials, customization options, professional installation, competitive pricing, and excellent customer service, they are the ideal choice for your epoxy coating needs. With proper maintenance, your epoxy coated aircraft hangar flooring can provide a long-lasting and reliable flooring solution for years to come.