Epoxy, Polished Concrete & Urethane Flooring — A Vancouver & BC Buyer’s Guide (2025)

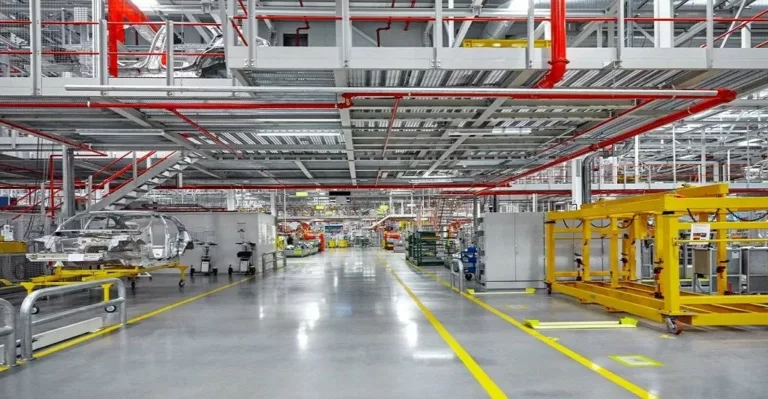

How epoxy coatings, polished concrete and urethane/polyaspartic systems compare for garages, parkades, retail, restaurants and industrial floors across Vancouver & British Columbia.

In Metro Vancouver, concrete floors deal with rain, grit, UV, temperature swings and constant traffic. The wrong system can peel, dust or stain long before its “advertised” lifespan. The right system, installed properly, can look sharp and perform for many years.

This guide from Priority One Epoxy Flooring explains when to choose epoxy, polished concrete or urethane / polyaspartic so you get the best mix of performance, style and value for your space in Vancouver or anywhere in BC.

Three proven options for Vancouver & BC concrete floors

Epoxy coatings — seamless protection with design flexibility

Epoxy is a two-part resin that bonds to prepared concrete and cures into a dense, seamless surface. It’s popular in Richmond, Surrey and North Vancouver garages because it combines durability, cleanability and custom design. You can go simple and solid, choose decorative flake, or create a metallic “showroom” look.

- Best fit: garages, workshops, showrooms, light industrial, clinics and labs.

- Key strengths: chemical resistance, easy cleaning, line marking and safety zoning, wide colour/options.

- Build options: thin-mil for light duty; high-build and mortar systems for impact zones; UV-stable clear topcoats at doors and exterior edges.

Polished concrete — natural aesthetic, long life, low maintenance

Polished concrete is a mechanical process, not a coating. The slab is ground, densified and polished to a chosen sheen. There’s no topical resin on top, which means excellent UV stability and a very low-lifecycle-cost, minimalist finish.

- Best fit: retail, restaurants, lobbies, studios, galleries and large warehouses.

- Key strengths: modern look, no peeling, great light reflectivity, minimal ongoing products.

- Options: matte to high-gloss; different aggregate exposure levels; stain-protection plans and inlaid striping.

Urethane & polyaspartic — UV-stable, fast-cure protection

Urethane and polyaspartic topcoats bring high abrasion and chemical resistance plus rapid return-to-service. They’re often used over epoxy base coats or as part of parkade and ramp systems where downtime is expensive and UV exposure is constant.

- Best fit: condo parkades, ramps and aprons, food & beverage, heavy-traffic retail.

- Key strengths: excellent UV stability, tough top surface, faster turnarounds than traditional epoxies alone.

- Options: clear or pigmented finishes, slip-resistant textures, high-build protective layers.

Epoxy vs polished concrete vs urethane/polyaspartic

All three systems can work extremely well when specified correctly. The table below shows how they compare on some of the most important decision points.

| Criteria | Epoxy | Polished Concrete | Urethane / Polyaspartic |

|---|---|---|---|

| Downtime / cure | Light traffic in ~24–72 hrs; full cure up to 7 days depending on system & temperature. | Can often be phased; no resin cure, just waiting on densifier/drying and cleaning. | Fast cure; some systems reopen in 2–24 hrs for foot and vehicle traffic. |

| UV stability | Standard epoxies need a UV-stable topcoat in sunny or exterior areas. | Excellent, as there is no topical resin layer to yellow. | Excellent; engineered for exterior and high-UV environments. |

| Chemical resistance | Strong; can be upgraded with high-build or mortar systems in harsh zones. | Good with the right guards and maintenance; spills should still be managed quickly. | Excellent; preferred for food & beverage, parkades and production with aggressive cleaning. |

| Design options | Solid colours, flake blends, metallic effects, line markings and logos. | Matte to high-gloss, control over aggregate exposure, integral “architectural” look. | Clear or pigmented topcoats, different textures and gloss levels. |

| Typical use cases | Garages, shops, retail, labs, clinics, corridors, plant floors. | Retail, restaurants, lobbies, galleries, warehouses. | Ramps, outdoor aprons, parkades, wash-down areas, fast-turn jobs. |

| Budget (installed) | $$ — strong value; can be scaled heavier where needed. | $$ — very competitive lifecycle cost; low consumables. | $$$ — higher material cost offset by reduced downtime and high performance. |

Built for BC: prep, moisture control & detailing

In our climate, prep and moisture control decide how long floors actually last. Priority One Epoxy Flooring follows a process designed for coastal BC and the Interior:

- In-slab RH and moisture checks where needed (ASTM-style testing).

- Mechanical profile via diamond grinding or shot-blast—no acid etch.

- Crack chasing, joint rebuilds, patching and levelling before coating or polishing.

- Dust control and edge detailing for clean transitions.

- Systems matched to traffic, chemicals, UV exposure and cleaning methods.

- Clear, written scopes with build details and cure times.

- Handover instructions: when you can walk, park and wash.

- Maintenance guidelines so you know how to protect the finish long term.

Pricing guide for Vancouver & BC (2025 ballpark)

Actual pricing depends on slab condition, prep, repairs, square footage and finish, but these ranges help with early budgeting:

- Epoxy (solid / flake / selected metallic): typically $8–$20 / sq ft, with heavier-duty and specialty effects higher.

- Polished concrete: typically $7–$18 / sq ft depending on grind level, densifier steps and sheen.

- Urethane / polyaspartic: typically $16–$28 / sq ft based on build, texture and cure speed requirements.

Example: A 450 sq ft two-car garage in North Vancouver might price at $5,400–$9,000 for a decorative flake epoxy system. A fast-turn urethane/polyaspartic build could range $7,200–$12,600 depending on prep and product selection.

Simple maintenance & fast decision guide

Whichever system you choose, a few habits dramatically extend lifespan:

- Use entrance mats and regular sweeping to keep grit off the surface.

- Clean with pH-neutral products unless your system is specified otherwise.

- Plan small, localized re-coats or touch-ups instead of waiting for major failure.

- Inspect ramps and thresholds after winter for salt and impact damage.

- Choose Epoxy if you want maximum design control and great performance for garages, shops, retail and light industrial.

- Choose Polished Concrete if you want a natural, modern look and low lifecycle cost for retail, restaurants, lobbies and warehouses.

- Choose Urethane / Polyaspartic if fast reopening, UV stability and abrasion resistance are your top priorities (ramps, parkades, F&B).

Will my new floor be slippery when wet?

Traction is tuned to your space. Epoxy and urethane can include non-slip aggregates, and polished concrete can be finished to target friction levels. Exterior ramps typically get a light texture for all-weather confidence.

How do you prevent peeling and bubbles?

Most failures come from poor prep or moisture. Priority One Epoxy Flooring mechanically profiles the slab, tests for vapor where needed, repairs defects and specifies primers/topcoats that match the site conditions.

How quickly can I use the space again?

Urethane/polyaspartic systems can reopen in 2–24 hours depending on build and temperature. Epoxy usually allows light traffic after 24–72 hours. Polished concrete can often be phased so parts of the space remain open while work is completed.

Do you provide a warranty?

Yes. Your written quote includes workmanship terms and product warranty details matched to your specific system and use case.

Priority One Epoxy Flooring provides on-site assessments, written specifications and turnkey installation for epoxy, polished concrete and urethane/polyaspartic systems across Vancouver and British Columbia.