Garage Floor Epoxy Installers in Vancouver, BC

Priority One Epoxy Flooring provides professional garage floor epoxy installation in Vancouver for homeowners who want a clean, durable, long-lasting finish. Our installers handle mechanical diamond grinding, moisture-aware prep, crack and joint repair, and precision system layering using flake, quartz, and metallic finishes with premium protective topcoats.

Garage Floor Epoxy Installers

Professional garage floor epoxy installation for Vancouver homes

Your garage isn’t just parking — it’s storage, a workshop, a home gym, and often the main entry. A premium garage floor epoxy coating should look high-end on day one and still feel “new” after months of wet vehicles, road salts, sand, tire marks, and daily traffic in Vancouver’s climate.

Based in Richmond, BC — serving Vancouver, Burnaby, New Westminster, North Vancouver, West Vancouver, Coquitlam, Port Coquitlam, Port Moody, Surrey, Delta, Langley, and Maple Ridge.

Our garage floor epoxy installers handle mechanical diamond grinding, moisture-aware priming, crack repair, controlled broadcast coverage, and premium clear-coat sealing for residential garages across Metro Vancouver—built around your slab condition, usage, and return-to-service timeline.

What makes a garage floor feel “premium”?

A luxury garage finish is clean, consistent, and intentional — and it starts with preparation. We build results around mechanical diamond grinding, correct repairs, controlled broadcast coverage, and a protective clear coat that improves cleanability and keeps the finish crisp.

- Adhesion-first preparation for long-term bonding and durability.

- Moisture-aware priming to reduce bubbling and delamination risk.

- Balanced traction so it feels safe without being hard to clean.

- Clean detailing at edges, stems, and transitions for a finished-room look.

Most failures start with shortcuts in preparation. A premium epoxy garage floor starts with the slab and ends with protective sealing chosen for how you actually use the space.

Why Vancouver garages need the right system

Vancouver garages see constant moisture cycles: rain tracking, puddling near the door line, humidity, and vapour drive through concrete. Add road salts, sand, tire plasticizers, and abrasion, and bare concrete becomes stained, dusty, and difficult to maintain.

- Wet seasons, slush, and road salt residue.

- Grit from sand, gravel, and driveway debris.

- Oil, chemicals, and tire marks from daily parking.

- Humidity and moisture pressure through the slab.

This page is dedicated to residential garage floor epoxy installation in Vancouver and the Lower Mainland — finish options, process, flake colours, and maintenance guidance for garage use.

Many homeowners are surprised by how much the garage changes once the dust and stains are gone. With a premium coating, the space feels brighter, cleaner, and easier to maintain day to day.

Finish Options

Three premium garage floor looks for Vancouver households

Most clients want a finish that looks intentional, hides daily dust, and stays easy to maintain. We typically recommend one of these three directions depending on style, traffic, and how you use the garage.

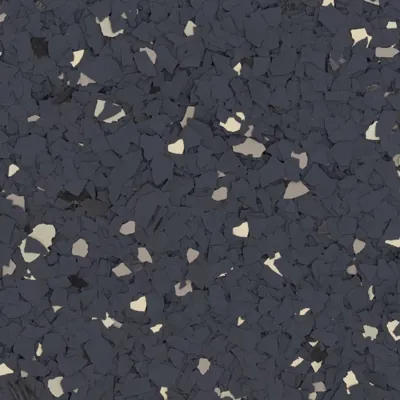

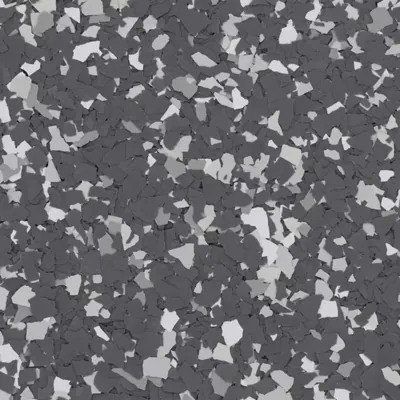

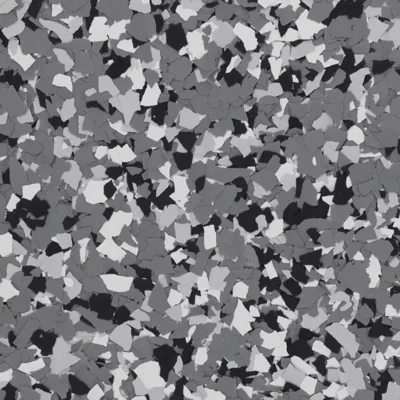

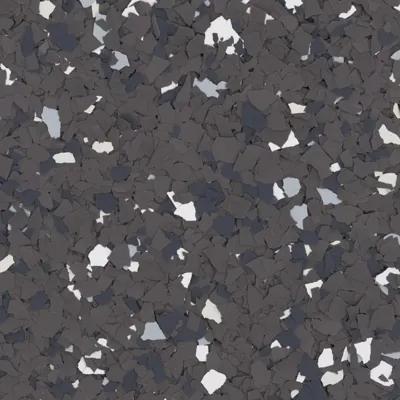

Full flake broadcast (most popular)

Full flake broadcast creates a consistent, design-forward surface that hides dust and tire marks while adding subtle texture. It’s the best balance of luxury appearance and practical performance for most Vancouver garages.

- Modern “finished room” look with uniform coverage.

- Excellent dirt-hiding and scratch-camouflage.

- Comfortable texture that stays easy to clean.

Quartz broadcast (performance + traction)

Quartz systems deliver refined texture and strong wear resistance. If your garage is a workshop, gym, or heavy-use space, quartz provides traction and durability while still looking premium.

- Excellent traction without looking “industrial”.

- High wear resistance for busy households.

- Great for utility zones and wet foot traffic.

Metallic (statement finish)

Metallic floors offer depth and movement similar to stone or liquid metal. They’re ideal when you want a standout, showroom-style look, best in garages that stay relatively clean and controlled.

- One-of-one visual depth and patterning.

- Showroom look when paired with a premium clear coat.

- Best for clients who want a luxury feature finish.

If you’re considering metallic, see: Metallic Epoxy Flooring Vancouver.

The best finish is the one that matches how you use the garage. Daily parking and low maintenance usually means full flake. Traction and toughness points to quartz. A signature visual finish points to metallic.

Project Looks

Premium garage textures and finishes (real installs)

These examples show the kind of luxury finish you can expect from professional preparation, consistent broadcast coverage, and premium clear-coat sealing. Images are displayed in consistent ratios so the page stays clean and upscale.

A luxury finish isn’t only about appearance. The right broadcast density, scraping method, and clear-coat selection creates a surface that cleans easily, resists staining, and holds up to daily parking without constant upkeep.

Installation Process

How a premium garage floor coating is installed

The difference between “looks good for a month” and “looks good for years” comes down to preparation and system design. Here’s the typical process our garage floor epoxy installers use for Vancouver and the Lower Mainland.

01 — Assess the slab and define the build

We inspect for cracks, spalling, old sealers or coatings, oil saturation, and moisture risk areas. Then we match the system to your use: daily parking, gym, workshop, storage movement, or heavy use.

- Concrete condition check and surface hardness variations.

- Old coating/paint identification and removal plan if required.

- Finish selection based on your style and cleaning preference.

A premium quote isn’t a guess. It’s a plan built around real site conditions.

02 — Mechanical diamond grinding and detail prep

Grinding creates the profile needed for mechanical bonding. We use diamond tooling to open the concrete, remove weak laitance, and create a consistent surface for coatings to lock into.

- Diamond grinding for a consistent bonding profile.

- Edge detailing so the perimeter looks finished.

- Thorough vacuuming to remove fine dust and debris.

03 — Crack repair and joint strategy

Cracks and joints need a strategy. We repair for appearance and performance while using methods that fit the slab’s condition and movement.

- Crack treatment and patching as required.

- Joint edge cleanup for a clean visual line.

- Localized repairs in spalled or weakened areas.

04 — Base coat, broadcast, and coverage control

We install the base layer and broadcast your finish. Full flake is the most common because it delivers uniform coverage and hides daily dust. Quartz can be selected for increased traction. Metallic is installed with technique and timing to build depth.

- Base coat designed for bonding and build.

- Full broadcast for consistent texture and luxury look.

- Clean cut lines and controlled edges.

05 — Scrape, vacuum, and seal

After broadcast, we scrape to remove vertical edges and create a comfortable, consistent texture. Then we vacuum thoroughly and apply a protective clear coat to improve cleanability and chemical resistance.

- Scraping for comfort, consistency, and quality control.

- Vacuuming and detail cleanup before sealing.

- Clear coat chosen for long-term durability and use.

06 — Cure + return-to-service guidance

We provide clear guidance for foot traffic, storage movement, and vehicles. Protecting the finish during early cure helps it reach full performance. For tight timelines, we can recommend faster-return options.

- Clear steps for parking timelines and protection.

- Maintenance tips for the first weeks of use.

- Long-term care guidance to keep the finish luxury.

A luxury garage floor is built, not painted on. When the slab is prepared correctly and the system is layered intentionally, you get a finish that feels premium every time you walk in.

System Guidance

Epoxy vs polyaspartic for Vancouver garages

Homeowners hear “epoxy”, “polyaspartic”, and “polyurea” and assume one is automatically best. In reality, a premium garage floor epoxy system is about the full build: prep, layers, finish, and protective sealing. If you’re deciding between the two most common options, read: epoxy vs polyaspartic garage flooring (Vancouver guide).

Epoxy (foundation and build)

Epoxy is commonly used for build layers because it provides strong film build and a stable base for flake or quartz. In garages, performance depends on prep and protective sealing.

- Strong base for flake and quartz broadcast finishes.

- Excellent build for a refined, consistent look.

- Best when protected with the right clear coat.

Polyaspartic (premium protection)

Polyaspartic is often selected as a protective layer for chemical resistance and improved colour stability near bright door openings. It’s a popular top-layer option for premium residential garages in the Lower Mainland.

- Strong protection for daily parking and cleaning.

- Excellent option for bright garages near the door line.

- Good fit when you need faster access.

Polyurea (specialty performance)

Polyurea is typically used when higher performance is required. The best choice depends on slab condition and how the system is specified. We recommend it when it genuinely matches the project needs.

- High performance when specified correctly.

- Good fit for certain heavy-use scenarios.

- Best selected after an on-site assessment.

Don’t chase a buzzword — chase the outcome: a garage floor that’s easy to clean, resists staining, and feels “finished” every time you walk in.

Flake Colour Catalogue

Premium flake blends for Vancouver garages

Choose a blend that matches your home: modern neutrals, warm stone tones, or darker luxury mixes. Use search to filter by name or code (example: “Raven” or “FB-915”).

If swatches don’t show, it’s almost always a file path/filename mismatch, mixed http/https, caching, or a CDN delay. This block uses 400×400 WebP images and will hide any broken items automatically.

Selection tip: If you park daily and want the lowest-maintenance look, choose a mid-tone blend that hides dust and small debris. If you want a brighter “clean garage” look, lighter blends can be stunning, especially with upgraded lighting.

Pricing & Value

What affects the cost of garage floor epoxy installation?

Garage floors are priced based on scope, preparation requirements, and finish selection — not just square footage. Two garages can be identical in size but require different prep depending on old coatings, crack repair, oil saturation, and moisture.

Concrete condition and preparation needs

Preparation is where long-term performance is earned. If the slab has weak concrete, old paint, sealers, or contamination, we address it properly so your garage floor coating bonds and stays bonded.

- Cracks, spalls, and joint edges that require repair.

- Old coatings or paint that must be removed.

- Oil or chemical contamination requiring additional prep.

- Uneven surfaces that need localized patching.

Finish selection and protective sealing

Full flake is often the best value because it looks luxury while staying practical. Quartz can be selected for traction and durability. Metallic is a statement finish and can involve more technique and finishing detail. Protective sealing is what keeps the finish clean and resistant to staining.

- Flake, quartz, or metallic finish complexity.

- Texture level chosen for safety and cleanability.

- Protective sealing selection based on exposure and use.

- Detailing around stems, thresholds, and transitions.

A garage coating is one of the most noticeable upgrades because it changes how the entire space feels: brighter, cleaner, easier to maintain, and more enjoyable to use.

Care & Maintenance

How to keep your garage looking “new”

A premium garage floor is simple to maintain, especially compared to bare concrete. A few consistent habits keep the finish bright and prevent grit from acting like sandpaper.

Weekly: quick sweep

Sweep or dust-mop to remove sand, driveway debris, and small stones. This is the simplest way to keep the finish crisp.

Monthly: light mop

Use a pH-neutral cleaner with warm water. Avoid harsh degreasers unless needed for a spot clean.

Seasonal: rinse door line

In rainy seasons and winter months, rinse and lightly mop near the garage door line to remove salts and grime from vehicles.

If your garage doubles as a gym or workshop, consider mats under heavy equipment and protectors under moveable storage. These habits reduce scratches and keep the luxury finish consistent over time.

FAQ

Garage floor epoxy questions Vancouver homeowners ask

If you’re comparing finishes or planning timing, these are the questions we hear most often in Vancouver and nearby areas.

How much does epoxy garage flooring cost in Vancouver?

Pricing depends on slab condition, prep needs (old coatings, crack repair, contamination), size, finish choice (flake/quartz/metallic), and the protective clear coat selected. After an on-site assessment, we provide a clear, itemized estimate based on what your slab actually needs.

How long does garage epoxy installation take, and when can I park?

Most residential garage installs are completed in a planned sequence of prep, coating, broadcast, and sealing. Return-to-service timing depends on the system and site conditions. After installation, we provide specific guidance for foot traffic, storage movement, and vehicle parking timelines.

Is a garage floor coating slippery when wet?

A properly designed system can include traction at the right level. Full flake and quartz finishes naturally add texture, and we can fine-tune grip so it feels safe without being difficult to clean.

Can you coat over old paint or a failing coating?

Often yes, but failing material must be removed and the surface mechanically prepared for bonding. An on-site assessment confirms what can stay and what must come off.

Do you repair cracks before coating?

Yes. Cracks and joints are addressed during prep so the finish looks clean and professional. Some slabs can still move over time, but proper repair improves appearance and performance.

Is polyaspartic better than epoxy for garages?

It depends on the build. Many premium garage systems use epoxy for build layers and polyaspartic as a protective clear coat. The best option depends on slab condition, exposure, and timeline—our epoxy vs polyaspartic guide explains the differences for Vancouver garages.

Ready to upgrade your garage?

Tell us the size of your garage, how you use it (parking, gym, workshop), and the finish you like (flake, quartz, or metallic). We’ll recommend the best system for your slab and timeline so it looks luxury and performs long term.

Prefer email? info@priorityonepoxyflooring.com