Commercial & Industrial Epoxy Floor Coatings: Benefits & Real-World Applications

What epoxy floor coating systems do best in warehouses, plants, food facilities and healthcare environments — plus common specs, limitations and maintenance practices.

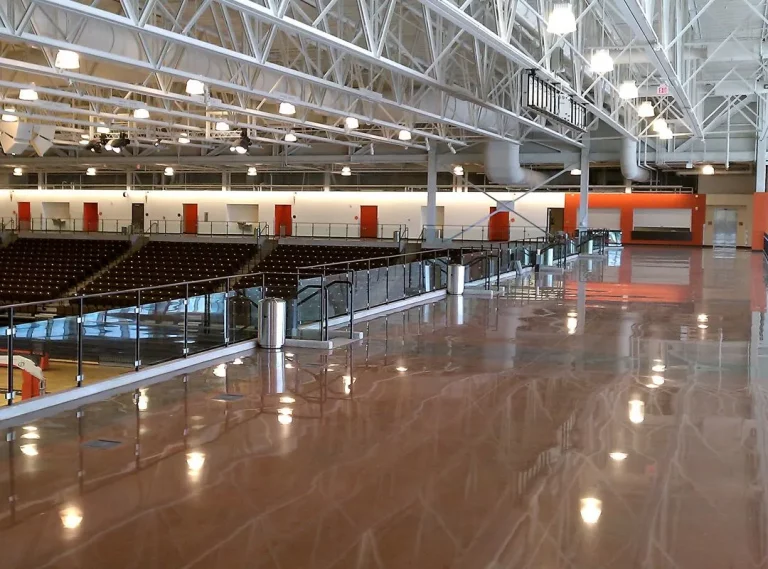

In demanding commercial and industrial environments, the floor is a critical piece of infrastructure. It has to handle forklifts, pallet jacks, chemical spills, constant traffic and safety audits—often 24/7.

Properly specified epoxy floor coating systems provide a seamless, chemical-resistant surface that is easier to clean, safer to work on, and more cost-effective over the life of a facility. This guide breaks down what these systems are, the benefits that matter most, and where they perform best.

If you’re planning upgrades for specific Metro Vancouver facilities, see our local overviews for epoxy flooring Burnaby and industrial epoxy flooring Richmond.

What are commercial & industrial epoxy floor coatings?

Epoxy floor coatings are multi-layer resin systems installed over properly prepared concrete. A resin and hardener combine to form a dense, seamless surface that bonds to the slab and cures into a durable, non-porous floor.

In commercial and industrial settings, coatings are usually built as spec-driven systems (primer, body coat, optional broadcast, and topcoat), with thickness and texture chosen to match traffic, impact, cleaning methods and chemical exposure.

Key benefits in commercial & industrial settings

- Handles forklifts, scissor lifts, pallet jacks and loaded racking.

- Resists abrasion from turning wheels, drag loads and frequent traffic.

- High-build and mortar systems protect concrete from chipping and spalling.

- Extends slab life and helps defer costly structural repairs.

- Protects concrete from oils, fuels, coolants and process chemicals.

- Helps contain spills so cleanup is faster and more effective.

- Reduces staining and degradation in production and wash-down zones.

- Simplifies spill response and supports safety programs.

- Slip-resistant textures for docks, wash bays and entry zones.

- High-reflectance finishes improve lighting and visibility.

- Integrated line striping, walkways and safety zones.

- Supports audit readiness with consistent zoning and housekeeping.

- Non-porous surface leaves no grout lines to trap dirt.

- Performs well with routine disinfection and scrubber cleaning.

- Reduces time and chemical use for daily maintenance.

- Common in food, beverage, healthcare and controlled environments.

- Solid colours for production; decorative flake for showrooms and lobbies.

- Colour zoning to support traffic flow and safety programs.

- A clean, professional finish modernizes older facilities.

- Helps standardize housekeeping and reduce concrete dusting.

Epoxy vs urethane cement vs polyaspartic in industrial projects

Epoxy is often the backbone of an industrial floor, but other resins (urethane cement and polyaspartic) are used as companions or alternatives depending on heat, moisture and cure-speed requirements.

| System Type | Best Used For | Key Strengths | Main Considerations |

|---|---|---|---|

| High-build Epoxy | Warehouses, production, retail back-of-house, many parkade interiors. | Excellent adhesion, chemical resistance and wear when built correctly. | Standard epoxies aren’t UV-stable; exposed areas usually need a UV-stable topcoat. |

| Epoxy Mortar | Impact zones, forklift paths, slab rebuilds and heavy point loads. | Very high compressive strength; rebuilds worn or pitted concrete. | Higher cost; typically used in targeted lanes or high-abuse zones. |

| Urethane Cement | Food plants, wash-down areas, thermal shock environments. | Handles hot water, steam, thermal cycling and aggressive cleaning. | Specialized system; often reserved for wet/hot zones rather than entire buildings. |

| Polyaspartic (often as topcoat) | Fast-turn areas, entry zones, UV-exposed aprons/ramps. | Rapid cure, strong abrasion resistance and excellent UV stability. | Conditions must be controlled; cure speed requires experienced crews. |

Where epoxy flooring systems perform best

Epoxy floor coatings are widely used in environments that require durability, safety and cleanability at once:

- Warehouses & distribution: high-build epoxy with demarcated forklift lanes and safety striping.

- Manufacturing plants: chemical-resistant epoxy with defined staging and pedestrian paths.

- Food processing / kitchens: epoxy or urethane-cement in wet zones with traction and coves.

- Retail & showrooms: decorative epoxy finishes that handle traffic and clean easily.

- Healthcare & labs: seamless finishes compatible with disinfectants and rolling loads.

- Loading docks & service corridors: impact-resistant systems in turning and threshold areas.

Design & maintenance practices that protect ROI

Industrial floors perform best when they’re designed for real workflows—traffic patterns, cleaning methods, and future equipment changes. These practices keep floors looking good and reduce lifecycle cost:

- Match system thickness to traffic (forklifts vs. carts vs. foot traffic).

- Address moisture and slab condition before choosing products.

- Detail joints, drains and transitions in wet or wash-down zones.

- Plan striping and zoning early (walkways, storage, hazard areas).

- Remove grit that acts like sandpaper under wheels and shoes.

- Clean spills—especially oils and process fluids—promptly.

- Use compatible cleaners (avoid film-forming products unless specified).

- Maintain wheels, skids and dock plates to reduce gouging.

- Inspect turning lanes, thresholds and dock edges for wear.

- Re-topcoat high-wear lanes before the body coat is exposed.

- Document repairs and maintenance for budgeting and audits.

- Recurring impact damage in the same zones.

- Change of use (heavier loads, new chemicals, wash-down added).

- New hygiene/safety standards requiring texture or zoning.

How long do epoxy floors last in warehouses and plants?

With proper prep, moisture control and an appropriate system build, industrial epoxy floors commonly last 5–10+ years. Many facilities extend lifespan by re-topcoating high-wear lanes before the body coat is exposed.

Are epoxy floors slippery in kitchens or wash bays?

They don’t have to be. Texture and aggregates are specified by zone so wet areas achieve traction while still being cleanable. Smooth finishes are often reserved for dry corridors and showrooms.

Can epoxy handle hot water and thermal shock?

Standard epoxies have limits with extreme thermal cycling. In hot-wash or steam-cleaned zones, systems such as urethane cement are often used because they’re designed for thermal shock.

What causes early failure in industrial epoxy floors?

Most premature failures trace back to poor prep and moisture (coating over smooth/contaminated/damp concrete). Correct mechanical prep and moisture testing are the foundation of long-term bond.

Can industrial epoxy work be phased to reduce downtime?

Yes. Many facilities phase work around equipment and schedules. Cure time depends on system design, but staged areas and fast-cure layers can reduce disruption.

This article explains benefits and applications at a high level. For epoxy flooring systems, service areas, and installation details, see our epoxy flooring service page.